|

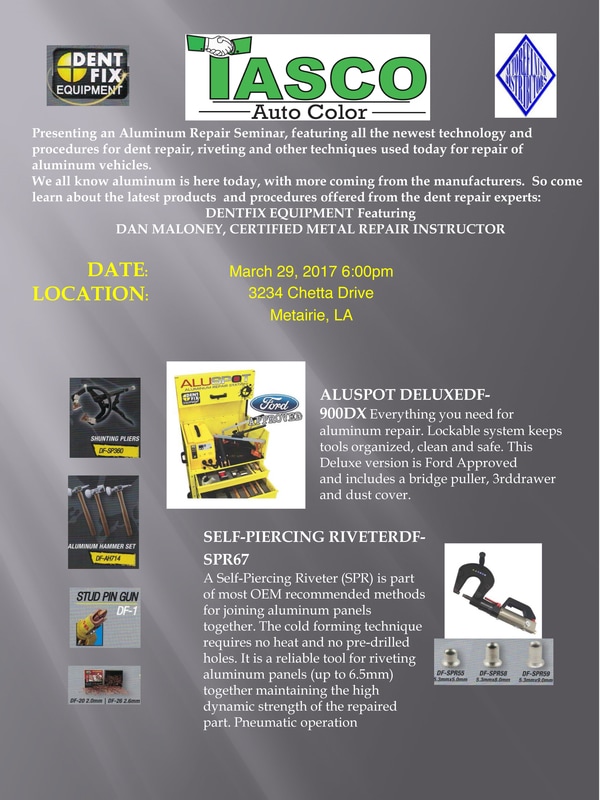

Tasco Auto Color in Metairie will be hosting an Aluminum Repair Seminar on March 29, 2017. Stop on by and see the latest technologies used for dent repair and more.

1 Comment

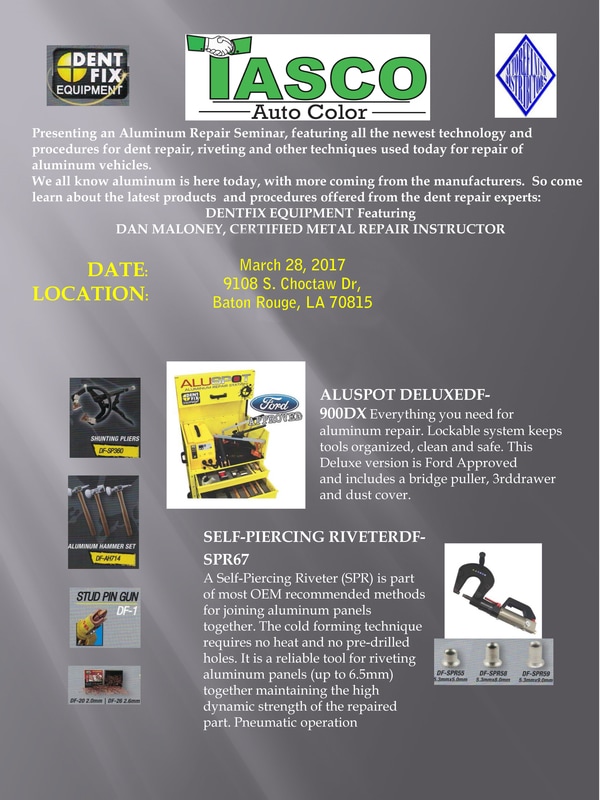

Tasco Auto Color in Baton Rouge will be hosting an Aluminum Repair Seminar on March 28, 2017. Stop on by and see the latest technologies used for dent repair and more.

Team Tasco (Corey from #24, Christie from #25, Sonia from #1, Mario from #2 and Adam from #17) made the trip to SEM School in Rock Hill, South Carolina to do some training. The SEM training class was so beneficial in product knowledge and usage allowing team members to learn and have some fun. The training consisted of bumper repair, adhesives, vinyl prepping and more.

The team was able to do some go-karts and take in the local scene involving Stewart Haas Racing (Tony Stewart, Danica Patrick, Kurt Busch and Kevin Harvick).

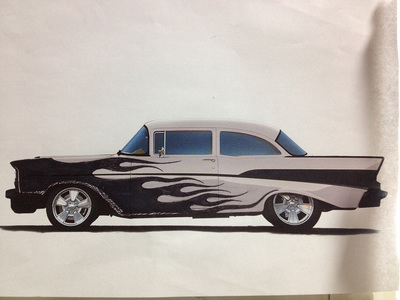

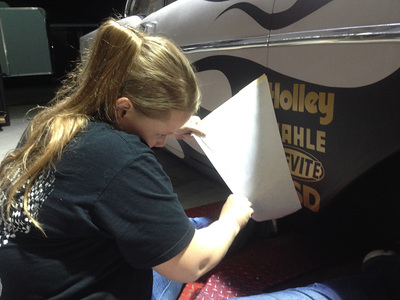

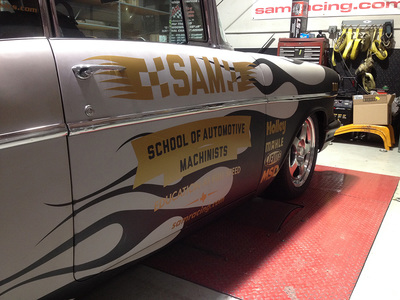

The 57 Chevy Story Houston, Texas - Tasco Auto Color is proud to be a sponsor of the The 57 Chevy Hot Rod Power Tour 2015 car built by a team from Houston's own School of Automotive Machinists. The School of Automotive Machinists (SAM) is an accredited career college with Block, Head, & CNC Machining and Associates Degree Programs. The graduates work for the racing industry's best. The SAM '57 Chevy Build Team has worked for 2 months to build a resto-mod '57 Chevy Bel Air for the 2015 Hot Rod Power Tour. Check the tour dates above as the team left Texas to begin their tour nearly 3,000 mile journey in Wisconsin on June 7th and will conclude their journey on June 12th in Louisiana. More information, media and updates can be found at their SAM Racing facebook page. This 1957 Chevy Bel Air, owned by Judson Massingill (who is the owner of The School of Automotive Machinists right here in Houston), has been sitting for 15 years. A previous school team had attempted to build this car and did not pull through. This year, with a strong team and not a lot of time (two months to be exact), this car has been completely transformed. Tasco Auto Color/Landmark Marketing Company's own Jackie Perry was a key contributor in the 57 Chevy Build. Jackie (JAX Art & Design) helped with everything but the main things she did in her spare time was the production photography, designing the paint/color scheme, laying out the flames, designing vinyl layouts, setting up files for Redline and installing the vinyl. The 57 Build Team Members Michael Wilson from VA, John Gwinn from Michigan, Matt Petz from California, Oscar Zabek from New Jersey Sponsors Holley, Mahle and Clevite, MSD ignition, Muscle Rods, Tasco Auto Color, SPC Rods and Classics, LizardSkin, Bad Company Inc, JAX Art & Design Stages of Production Stage 1: First Steps The chassis and rear end housing along with a number of other parts have been powdercoated by SPC Rods and Classics. SPC Rods and Classics let the team use their facilities for all the bodywork. Going with an old school hot rod look, the team decided to leave the car in primer and lay flat black flames over it. Tasco Auto Color donated high end products including PPG Hot Rod Black, PPG JP285 Urethane Surfacer (primer), PPG DCC9300 Acrylic Urethane, PPG DCX61 High Solids Hardener, Evercoat Rage Extreme lightweight body filler, 3M 1/8” vinyl fine line tape, 1 1/2” and 3/4” 3M masking tape, roll of masking paper, a SATA spray gun rebuild kit, 34 oz DeVilbiss spray gun cup liners, pack of 1/8” and 1/2” spot weld drill bits. Stage 2: Sanding and Prepping for Paint Steps include taping and masking the trim off so it doesn’t get damaged, sanding the clear off to get to the underlying layer of paint unless there’s rust underneath that. In that case, it has to be sanded down to bare metal in order to remove the rust. Upon some sanding, the team found a huge crack in the rear quarter panel and turns out it was about a pound of body filler! We sanded it all out and reapplied Overcoat Rage Extreme lightweight body filler. Plenty of hours went into bodywork and sanding. Much of the 19-20 hour days went into this car, all the way til the end. The team had a strict deadline to make — the morning of June 4th. Stage 3: Painting The team painted the inside of front fenders and inner fender wells separately since they were already off the car. They gave the car three coats of primer and then wet sanded it so it would appear smooth and has a sheen when viewed at an angle, yet remains flat when looking directly at it. Stage 4: Taping Flames Jackie did a quick rendering of the car and then hand drew flames on it to be sure they looked exactly how she wanted them to. Starting these flames was semi-challenging, she had to get used to the 3M 1/8” blue vinyl fine line tape as she says "I’d never used it plus I’ve never done anything like this before. But the whole process was super smooth, it came very naturally to me." She started on the driver’s side, then traced it on paper, flipped the paper to the passenger side, and transferred the flames to the passenger side then taped them off. It took her a good 8 hours to do this entire flame layout process. Then they used the paper she traced to cut two stencils out of the paper to mask the body off for painting the flames. Stage 5: Paint Flames and the Big Reveal There are Real Flames! Jackie put down the first coat of PPG Hot Rod Black but passed the gun on because it was a first time painting through a spray gun and she admits to not moving quick enough. Three coats of black and 45 minutes of drying time later, they removed all the tape and masking and —VOILA! There are flames! They were ecstatic with the PPG Hot Rod Black paint and the way the flames turned out. FANTASTIC paint! Jackie says, "We also love the Dusty Rose color of the primer with the black. It really reminds us of a hot wheels car." Stage 6: New Floorboards, Lizardskin Prep and Application LizardSkin is a water-based spray-on insulation. The crew used Sound Control on the interior and Ceramic Insulation on the undercarriage. They installed new floorboards, primed them and seam sealed them with 3M Seam Sealer prior to LizardSkin application. Stage 7: Engine Assembly and Install The engine going in is an LS3 (came in Corvettes and 5th Generation Camaros), with cam swap and new heads, and a custom intake manifold built by the school. The only thing we kept stock was the bottom end (crankshaft and pistons). This car needed everything from the engine to the exhaust. New brake master cylinder, brake lines, transmission, driveshaft, rear end, fuel tank, etc. EVERYTHING is new. This lucky 57 is getting a new lease on life after sitting unloved for years. Stage 8: Wiring and Final Installations Start Your Engines! Along with new engines assembly, also has to come with wiring. The team got an entire wiring harness along with the new Holley EFI Dominator ECU (computer). When that was all done, they reinstalled the front fenders, hood, put all necessary fluids in, put the interior back in, installed the bumper and headlights. Stage 9: Finishing Touches The team had a few final adjustments to make but overall she’s looking great and ready to go! The new custom wheels finally came in and mounted them the same day. Then she was taken to get an alignment. Stage 10: Vinyl Install Vinyls were cut/printed by Redline Graphics in Houston. The team had agreed they couldn’t spare three hours for it to be at Redline for an install, so Jackie installed all of the vinyl graphics at the school. The gold vinyl is perfect and ties the entire color scheme together. Successful build? I’d say absolutely. Articles Meet the Students of the School of Automotive Machinists - The ’57 Bel Air that Wouldn’t Have Been - theblock.com Welcome to Power Tour 2015 - Hot Rod Network The SAM 1957 Long Hauler - MSN, Hot Rod Magazine SAM Racing Students Took This '57 From Heap to Pro Tourer in 8 Weeks - LSXtv Gallery Check out the latest photos, brought to you by Ric Vega. Cars of the Hot Rod Power Tour Sam Racing Day 0 Hot Rod Power Tour Day 1 Hot Rod Power Tour Day 2 Hot Rod Power Tour Day 3 Hot Rod Power Tour Day 4 #PowerTour2015

“We are happy to have the Pick’s For Paint team join us here at Tasco Auto Color” says David Abrahams, President of Tasco Auto Color. This addition creates a Tasco Auto Color presence in the New Orleans metro market and solidifies their coverage of Southern Louisiana. Pick’s For Paint was one of the original PPG Platinum distributors and founder Larry Pickering was a major contributor to many Jobber Councils and Forum Groups. Providing automotive paint since 1976, Pick’s For Paint has a great deal of experience to bring to Tasco. Many of the Pick’s For Paint employees will continue to provide service to their clients under the Tasco Auto Color banner. According to David Abrahams, “This transition should be easy for our clients and team members. Both Tasco Auto Color and Pick’s For Paint are family focused businesses that align with a commitment to total client satisfaction as PPG Platinum distributors.” Tasco Auto Color #25 - 3234 Chetta Dr, Metairie, LA 70003

|

Connect

Tags

All

Archives

June 2024

|

Tasco Auto Color | Paint Distribution of Refinish Coatings to the Auto Body Repair Industry

|

|