Have you checked your spray gun’s fan pattern recently?

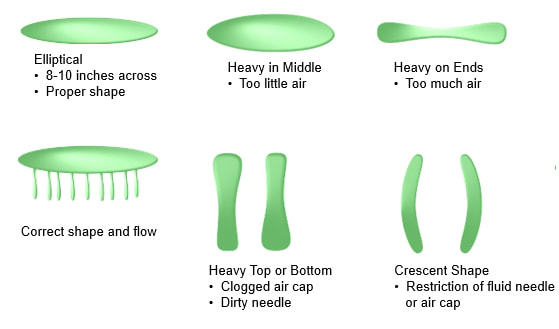

You should always check your gun’s fan pattern prior to material application. Holding your gun 6-9” from a piece of masking paper or other flat surface, spray your paint to check for a uniform, elliptical pattern. Other fan patterns can indicate a problem and should be fixed.