Don't Destroy Your Dies

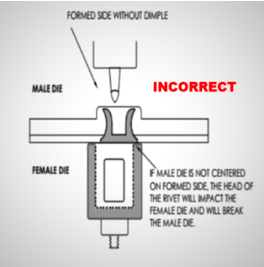

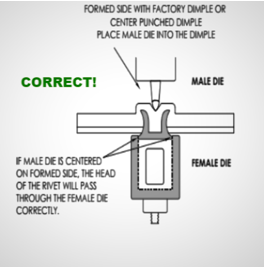

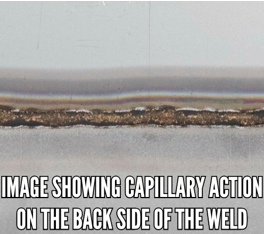

Ensuring Correct Alignment on the Backside of an SPR During Removal with the PR-5 Riveter is Essential!

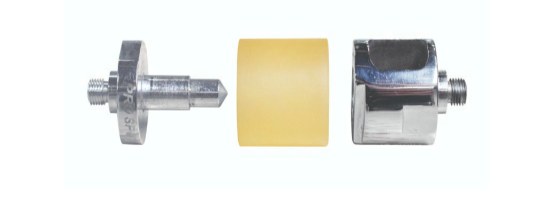

Heavy Duty Dies are expensive! Spare your wallet by following the proper procedures.

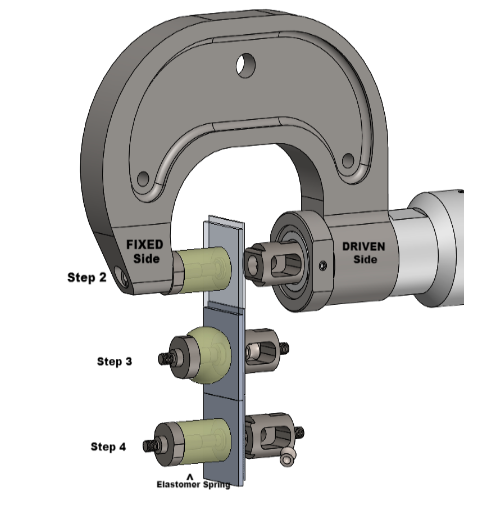

| Step One

| Step Two

|

| | |

| Step Three

| Step Four

|

| For more Tech Tips and Videos, visit the ProSpot YouTube Channel and subscribe to stay updated! |